Supreme COlour Physics Expert -- Optimal Solution for Total Colour Management

SCOPE features:

Textile Formulation

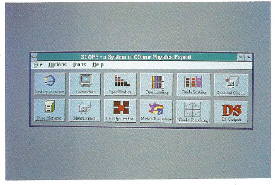

Application The textile industry is facing challenges to supply a larger variety of coloured batches against a background of environmental awareness, Gain SCOPE is a powerful, new generation, colour physics software designed to give production efficiency. Gain SCOPE uses Windows™ based software enhanced with powerful graphic functions. It is capable of driving a wide range of spectrophotometers, and provides comprehensive functions such as colour quality control and recipe formulation comparable to an expert. |

True Colour Simulation  Gain SCOPE employs unique technology to calibrate the monitor. The predicted colour can be accurately simulated under different illuminants, thus , reducing the time and cost of sample preparation. |

|

Expert Match

Gain SCOPE offers many techniques to obtain formulations: - Corrections for Lab and Production ¡@ |

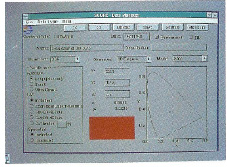

Dyestuff Loading

Two sets of calibration data, with unlimited concentration levels per dyestuff, can be loaded for achieving accurate recipe. Each dyestuff's 1/1 Standard Depth can also be predicted for QC purpose. |

|

Expert Tolerancing

The expert Tolerancing function enables users to setup individual customers requirements and optimize them based upon commercial biases. |

Colour

Specification & Quality Control

The R%, K / S, CIE colorimetric values and the Munsell coordinates can be displayed and plotted. Comprehensive QC functions include Whiteness, Colour difference, Colour fastness, Standard Depth, Strength, Metamerism, Opacity and Brightness. "Colour Constancy" and "Colour Appearance" functions can predict the change of colour appearance of a single sample prior to its production. |

Other Features

The system applies the CMC (1:c) macro colour space for shade sorting. This ensures that batches in each lot can be used in a single garment. The Shade library stores each shede¡¦s historical recipes. The Spectral Check function ensures that the instrument used is always in the best working condition.

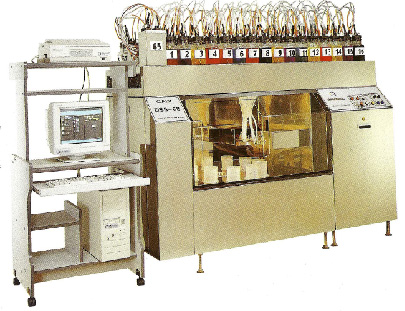

Total Colour Management

The formulation obtained from Gain SCOPE can be ported to Gain Dispenser for achieving accurate physical samples.

¡@

GAIN SCOPE specification

QC Version:

|

CIE Illuminants |

A / C / F2/ F7/ F11/ D50/ D55/ D65/ D75/ U30/ User defined |

|

Observers |

2˚, 10˚ |

|

Spectral data |

Reflectance ,transmittance , K/ S |

|

Spectral traceability |

Short, long term |

|

Colour specification |

CIE X, Y, Z/ x, y, z / CIE L*, a*, b*, c*, h* / CIE L*, u*, v* / HunterLab ANLAB, OSALgl / Munsell |

|

VDU calibration /High fidelity colour display |

|

|

Colour difference formulas |

CIE L* a* b*, CIE L *u*v*, Hunter L, a, b, FMC-II, AN LAB, JPC79, CMC(1:c), BFD(1:c), BFDA(1:c), CIE94(KL:KC) |

|

Expert tolerancing |

|

|

Whiteness |

ASTM(E313), Ganz Griesser, CIE , Berger, Harrison, Hunter, Stephansen, Stansby, Taube |

|

Yellowness |

ASTM 1925 ,ASTM E313 |

|

Opacity |

Contrast ratio , TAPPI T519 |

|

Optical density |

|

|

Brightness |

TAPPI T525, ¢HZ |

|

Colour constancy |

von Kries, BFD , CIE TC1.32, CIE L* a* b* |

|

Colour appearance |

Hunt 94, LLAB |

|

Colour strength |

Chromatic, Apparent, Unit price, Unit concentration |

|

Shade sorting |

555 CMC macro-space, 555*a*b* |

|

Expert sorting-Multi-standard. |

|

|

Standard depth 1/1 (ISO 105-A06) |

|

|

Colour tastness |

staining( ISO 105-A04), colour change (ISO/TC 38/SC 1) |

|

Step dyeing |

process profile, dye absorption record |

|

Shade library |

Recipe list, batch record, manual creating/editing recipe |

|

Shade search |

Shade search according to colour difference and cost |

|

Graphics |

Spectral curve, Trend charts, Histograms (sorting), |

|

Colour difference (Sphere, Ellipsoid) |

|

|

Save to ASCII file |

Colour samples, All result files |

Full version

All features in QC version PLUS:

|

Dyestuff Calibration |

Surface correction factor, standard depth 1/1, graphics for R, K/S Vs. wavelength, K/S vs. concentration, CIE L* a* b* plot |

|

Matching |

Job queuing, matching , status indication, multi-standard input, |

|

Substrate, process and dye strength compensation, blends of cross- |

|

|

staining , dye classification , dye combination up to six |

|

|

Search Shade & Correction |

|

|

Output sorting |

Cost, Metamerism, Cost & Metamerism |

|

X , Y , Z match (giving Colour Constant indeed for second and third illuminants) |

|

|

True colour coded dyestuff list |

|

|

Manual Matching |

Computer starting point, percentage concentration Reduction/ increase, fixed amount, fixed range prediction , save Recipe/ synthesized reflectance , standard and match display , Dyestuff build-up diagram |

| Expert Prediction System | Specifying area in colour space. auto-excluding abnormal dyeings , choice of lab/ production dyeing , cut-off date , machine number and Dyeing Process |

| Correction | Auto locating recipes , laboratory and production correction , Exhaustion and Continuous dyeing , capability of fully use of waste colorants |

| Re-dye using coloured Substrate | |

Compatibility system:

Windows 2000 (with SP3 or above), Windows XP, Windows 7 (x86 version)

Language support:

English, Chinese

![]()

![]()